|

Just one year after announcing it would bring a clean-sheet design single engine turboprop (SETP) to market, Textron Aviation has unveiled the Cessna

Denali.

“The Cessna Denali will enter the market as the superior aircraft in its segment,” said

Kriya Shortt, senior vice president, Sales and Marketing, Textron Aviation. “The Denali is already

garnering interest and commitments because of its winning combination of features, including class-leading performance and ownership costs, as well as the widest and most comfortable

cabin in its segment, all backed by an unrivaled global factory-direct service network.”

The Cessna Denali name captures the rugged, yet refined qualities of the high-performance single engine turboprop aircraft. The program is targeted to achieve first flight in 2018 and

letters of intent are being accepted.

“The Denali will balance great handling characteristics with the enhanced capability of a high performance turboprop, making it a great step up airplane for piston owners who are ready for

more performance,” said Shortt.

A high-performance, clean-sheet design

The clean-sheet Cessna Denali is being designed to outperform its competition in capability, pilot interface and ownership costs. Engineered to achieve cruise speeds of 285 knots and full

fuel payload of 1,100 pounds, the Denali will have a range of 1,600 nautical miles at high speed cruise with one pilot and four passengers and will be able to fly from Los Angeles to

Chicago, New York to Miami, or London to Moscow.

“Simply put, no aircraft in this class even comes close to the Cessna Denali. We are confident

the Denali will quickly rise as the leader in the high-performance single engine turboprop

market,” said Shortt.

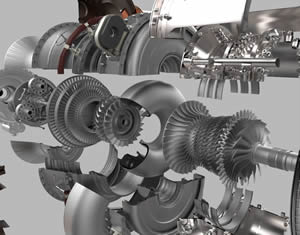

| The Denali will be powered by GE’s new advanced turboprop

engine and feature a handful of complex 3D-printed titanium and steel components

that will replace hundreds of individual parts.

The FADEC-equipped, 1,240 shaft

horse power (SHP)-rated turboprop engine will ease pilot workload with

its

single-lever power and propeller control. The airplane will be equipped with McCauley’s new 105-inch

diameter composite, 5-blade, constant speed propeller, which is full

feathering with

reversible pitch and ice protection. |

|

|

| The GE turboprop engine, featuring a number of 3D printed parts |

Image: GE Aviation |

The engine is designed to provide an initial 4,000 hour time between overhaul and offer

class-leading performance retention for an outstanding hot/high

capability.

The engine will burn up to 20 percent less fuel and achieve 10 percent more power than other engines in the same class.

Jeff Immelt, GE’s chairman and CEO, said the new machine

would generate $40 billion in revenue within 25 years.

The Denali will feature the Garmin G3000 intuitive touchscreen avionics suite and will include high-resolution multifunction displays and split-screen capability. The G3000 flight deck will

include weather radar, advanced Terrain Awareness Warning Systems (TAWS), and automatic dependent surveillance-broadcast (ADS-B) capabilities, which will make it compliant with a

significant aspect of future Next Generation air traffic control requirements.

Leading the passenger experience

The Cessna Denali’s flat floor cabin is designed to be the largest in its segment and will offer the versatility to easily convert between passenger and cargo configurations. The aircraft will

feature a class-leading 53-inch wide by 59-inch high aft cargo door, perfect for loading large cargo and ideal for use in many special mission applications.

|

|

The Cessna Denali's flat floor cabin is designed to be the largest in its segment and will offer the versatility to easily convert between passenger and cargo configurations. |

The Denali’s cabin will feature a standard seating configuration of six individual reclining seats and will offer a nine-place high density seating option. The aircraft will boast a digital

pressurization system maintaining a 6,130 foot cabin altitude at a service ceiling of 31,000 feet. First in this class of aircraft, the Denali will offer customers an optional externally

serviceable belted lavatory with pocket door enclosure that is located in the back of the cabin. Denali customers will also enjoy the large cabin windows, interior LED lighting, a forward

refreshment cabinet and an in-flight accessible baggage compartment.

Unrivaled factory-direct support

Denali customers will have access to Textron Aviation’s unmatched global service network dedicated to complete life-cycle support. Textron Aviation’s support organization includes 21

company-owned service centers located around the world with expert service engineers offering maintenance, inspections, parts, repairs, avionic upgrades, equipment installations,

refurbishments and other specialized services. In addition to its company-owned footprint, Textron Aviation’s turbine customers have access to a global network of nearly 200 authorized

service facilities. Textron Aviation also offers a mobile support program featuring more than 60 mobile service units, three dedicated support aircraft, and on-site service technicians and

support.

Along with a five-year limited warranty covering the airframe, engine and avionics, Denali customers can enroll in Textron Aviation’s industry leading ProAdvantage programs that have been

designed to provide customers lower, predictable ownership costs, while enhancing aircraft values through comprehensive factory-direct maintenance.

|