|

Material World By Anita Gradwohl, Group Director Customer Relation & Sales Business Unit New Market Aircraft Interiors, F/LIST. |

At F/LIST, we know what it takes to design an aircraft cabin. Whether pushing the boundaries of possibility, creating a relaxing haven, or creating a highly personalized space, we recognize that experts constantly seek new inspiration, concepts, and materials.

Decades of experience have shown us that the key to an extraordinary cabin experience is often in detail, and the most memorable details frequently rely upon beautiful materials.

It is in our DNA to source the finest quality materials from the world's leading suppliers, including our traditional wood and stone veneers. We literally travel around the globe to seek out a specific wood grain that meets the designer’s needs or source the perfect tone of a natural stone to ensure we deliver precisely what our customers need.

However, we are never satisfied with the status quo and always want to offer our customers never-before-seen options to ensure the creation of one-of-a-kind interiors. To satisfy this demand, we evolved the F/LAB. It is the center of innovation at our Austrian headquarters. It was developed to originate a whole spectrum of never-before-seen singular materials that enable new dimensions and styles in cabin interiors.

F/LAB is the melting pot where our experts and technicians experiment as they define new forms, concepts and products for the cabin, blending traditional craftsmanship with the latest technology to create advanced bio-based materials. The genesis of these elements was the need to support our F/LIST Shapeshifter concept, which defies physics by enabling the bending, morphing and transforming of seemingly fixed elements within the cabin. To ensure the required flexibility, we combined knowledge from different industries, F1, jewellery, and fashion, with our own aerospace heritage to devise materials that would allow us the flexibility we needed to produce our shapeshifting monuments.

The materials incorporate components that are making their debut in cabin interiors. Corn starch, apricot pits, mother-of-pearl buttons, luxury by-products from our stone milling, and a whole array of diverse elements can be customized to make spectacular surfaces for the cabin interior. From the beginning, we determined that these materials must be lightweight, bio-based and can be engineered for efficient recycling at the end of their useful life.

The products also had to look as good or better than their traditional equivalents and be equally durable in regular use. A sustainable product that must be replaced more often generates unnecessary waste, creates additional emissions through repeat manufacturing, and places a time and financial burden on the aircraft owner.

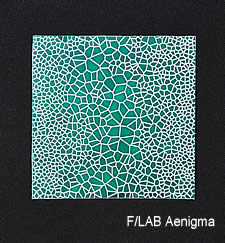

That’s why we are proud to offer a growing portfolio of cabin materials that offer attractive alternatives that inspire interior designers with new opportunities for expression. This is perfectly exemplified by the F/LAB Aenigma range.

Incorporating precious elements into a versatile material, F/LAB Aenigma is capable of presenting glistening geometric patterns and glowing surfaces, customized with colour, texture, and thickness for use on any cabin surface.

F/LAB Aenigma Smart seamlessly blends F/LAB Aenigma with extremely thin, bendable, fully liquid-resistant integrated sensory and interactive elements, allowing buttons and switches to be placed in areas, including curved edges, that were previously inaccessible to interactive technology.

Completing the range, F/LAB Aenigma Eco is a decorative rigid laminate suitable for customized pattern engraving; it helps bring the sustainability benefits of F/LAB Aenigma to every cabin area.

We know the materials our F/LAB experts create are extraordinary. And because we are also designers of spectacular spaces, we realize the importance of helping aircraft owners and operators define their vision. For this, we have curated a variety of resources, including the F/LIST Showpad, which includes a 3D rendering tool.

Pilatus PC-24-cross-section-incorporating-biobased-materials.

Ahead of the NBAA-BACE 2024 event in Las Vegas, we completed a Pilatus PC-24 cabin cross-section mock-up with a suite of bio-based F/LAB materials, including the new plant-based F/LAB Natural Oil varnish. Boasting the environmental credentials our customers expect of F/LAB, the transparent Natural Oil minimizes the release of harmful volatile organic compounds (VOCs), enhancing the grain and beauty of wood veneers with a subtle matt sheen and tactile finish.

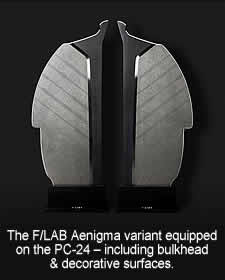

The Pilatus PC-24 cabin-cross section configuration balances the F/LAB Natural Oil-treated American walnut veneer with an F/LAB Aenigma Eco bulkhead incorporating recycled stone dust, an F/LAB Whisper Leather lower side panel, F/LAB Linfinium countertop incorporating marble remnants, and the natural lines of the F/LAB Fresco Décor on the upper side panel.

Pilatus has already included biobased materials in PC-24 refurbishments that are now flying, using the F/LAB Aenigma Eco as a bulkhead and is adopting more F/LAB materials in other refurbishment projects.

The installation of the novel materials demonstrates the increased demand, interest, and expectations from the business aviation sector for the potential to extend sustainability out of the fuel tank and into the cabin.

It also highlights our commitment to crafting innovation to enable the design of exclusive, sustainable, extraordinary cabins.

| © BlueSky Business Aviation News Ltd 2008-2024 |